Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

| Basic Parameters | Dimensions | L1450*W420*H290 (mm) |

| Maximum load | 500kg / 1000kg | |

| Body weight | 200kg | |

| Turning radius | 650mm | |

| Navigation Performance | Navigation | Magnetic Navigation |

| Navigation accuracy | ±10mm | |

| Stopping accuracy | ±10mm | |

| Athletic Performance | Walking direction | Forward, Turn left and Right |

| Drive mode | Differential drive | |

| Acceleration | 0.2m/s² | |

| Maximum walking speed | 45m/min | |

| Maximum gradeability | ≤3° | |

| Battery Performance | Battery type | Lithium battery |

| Charging method | Side charge / Ground charge | |

| Charging time | After full discharge, the charging time is less than or equal to 1H | |

| Rated battery life | 8H | |

| Network Performance | Communication method | RF / WiFi / 5G |

| Protection Performance | Safety warning | ●Light warning ●Voice broadcast |

| Safe sensing range | ≤3m adjustable | |

| Safety protection | ●Front obstacle detection sensor ●Mechanical anti-collision mechanism ●Emergency stop switch | |

| Application Environment | Operating ambient temperature | -10℃ ~ 45℃ |

| Operating environment | No dust, flammable, explosive and corrosive gases |

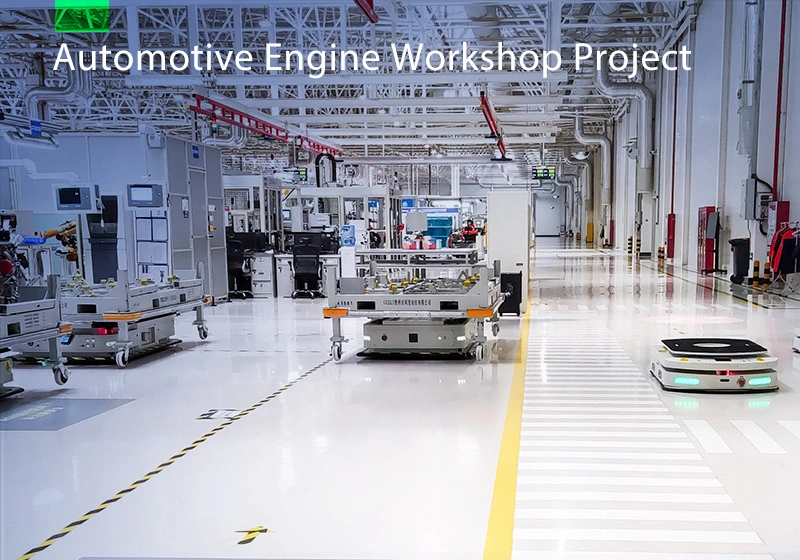

The AGV Material Handling's length is 1400mm and width is 420mm, workable in narrow space.

Mature rail navigation technology, acurate positioning and reliable working.

Equipped laser obstacle sensor / mechanical anti-collision bumper / acousto-optic alarm to ensure safe working environment.

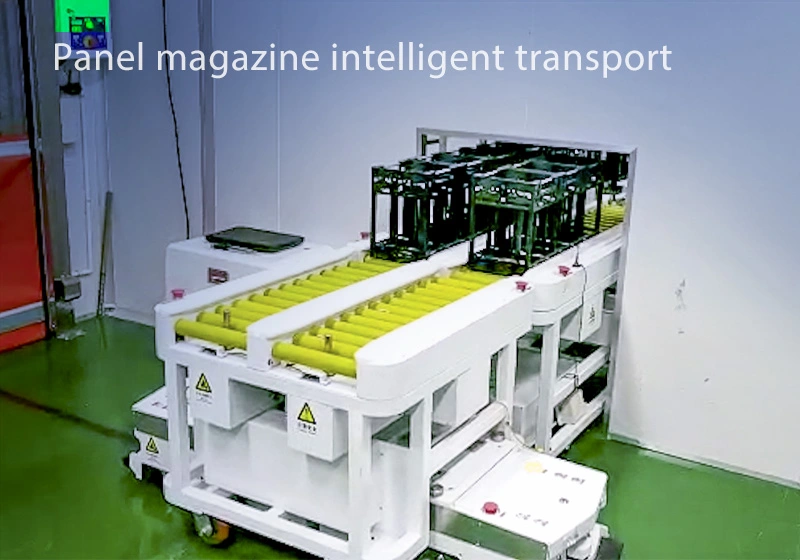

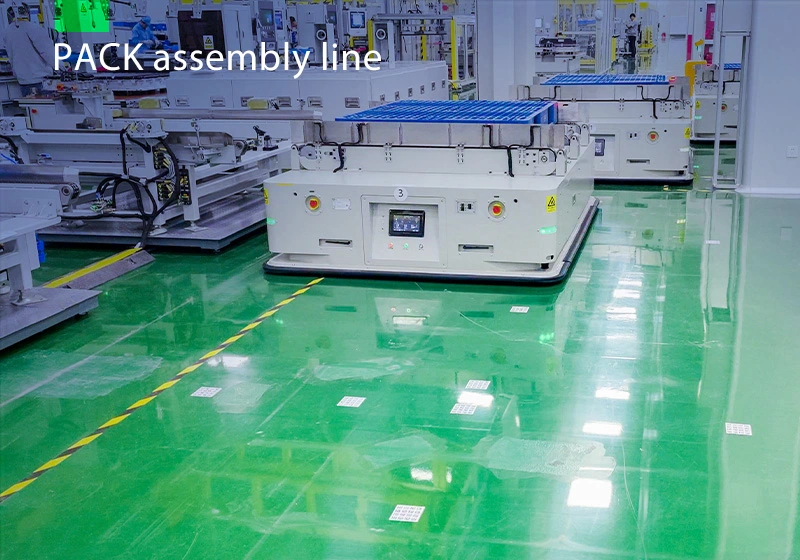

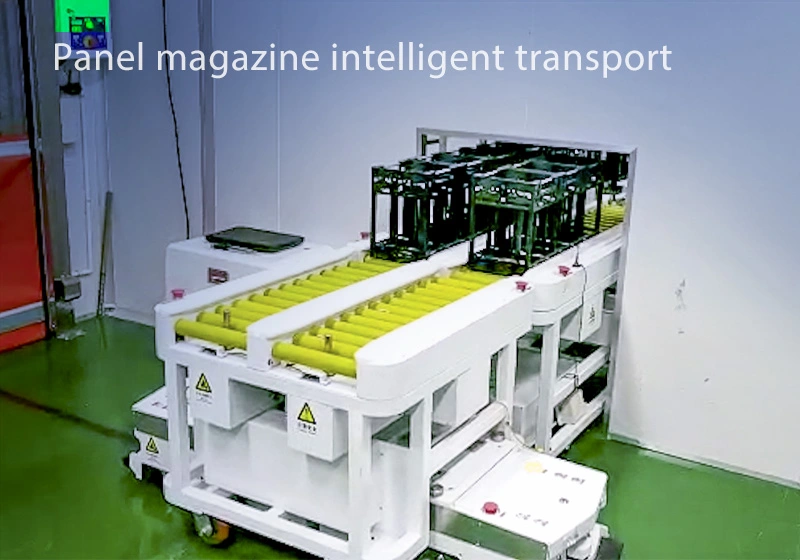

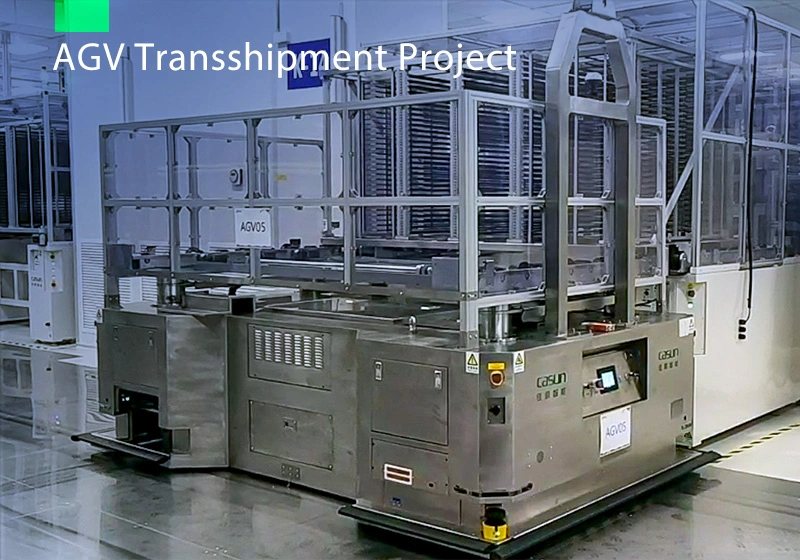

CASUN's self-developed Central Management Systems integrate high-frequency wireless communication technology, high-speed database analysis and processing technology, AGV digital control technology, combining on-site requirements to achieve intelligent scheduling of multiple AGVs.

AGV Material Handling will move to charge station and do charging job automatically when they are detected to be in low power status,response time can be 24 hours per day so as to increase productivity.

The L5 Mini AGV (Automated Guided Vehicle) is a small-sized forklift designed for material handling applications in various industries. Here are some common applications where the L5 Mini Forklift AGV can be used:

Warehousing and Distribution Centers: The L5 mini Forklift robot AGV can efficiently handle palletized goods in warehouses and distribution centers. It can transport pallets from one location to another, load and unload goods from shelves or trucks, and stack or de-stack pallets as required.

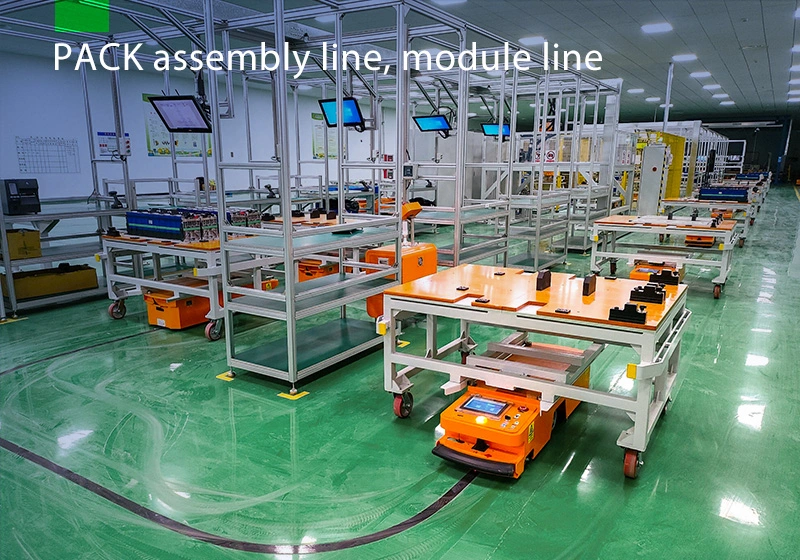

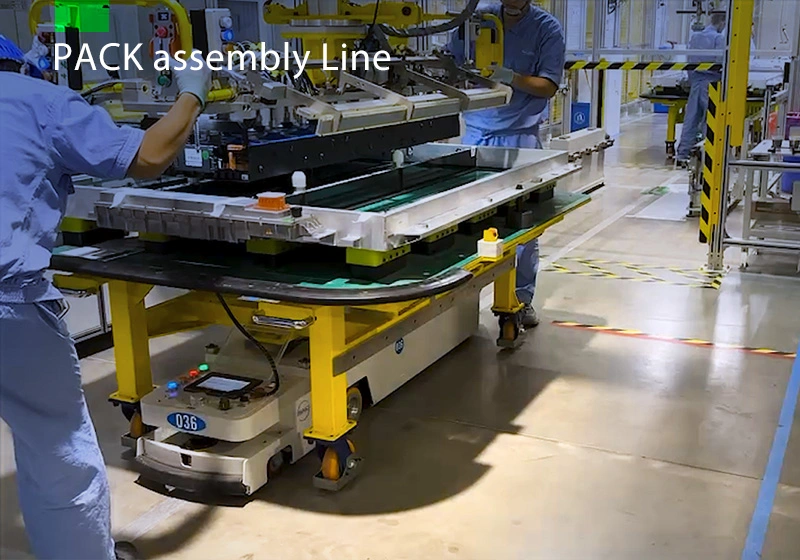

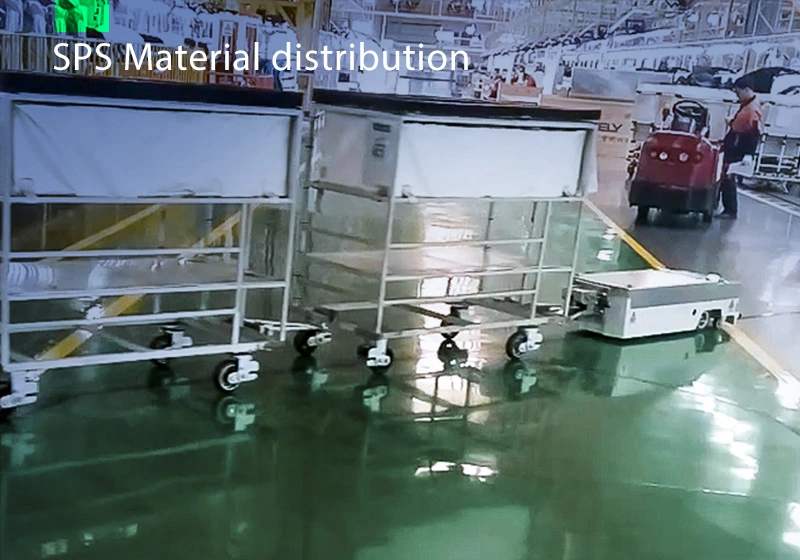

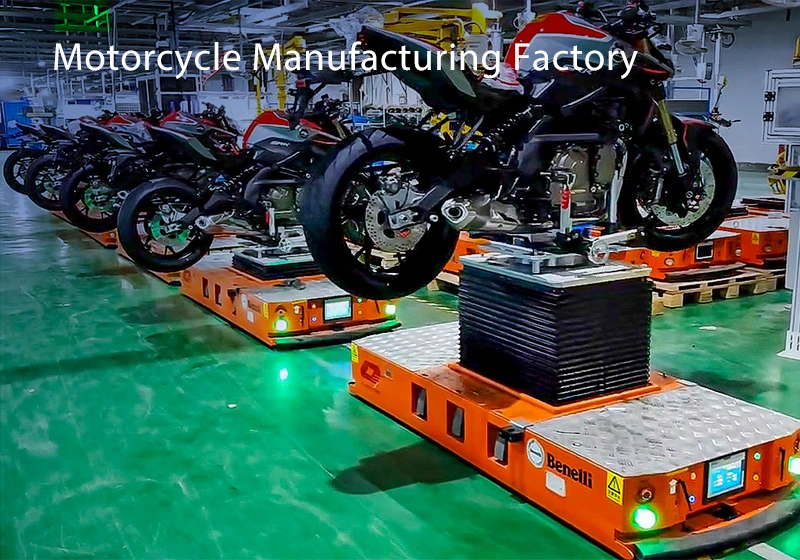

Manufacturing Facilities: In manufacturing plants, the L5 Mini Forklift AGV can assist in moving raw materials, work-in-progress items, and finished goods between different production areas. It can also transport components to assembly lines and deliver finished products to the warehouse or shipping area.

Retail and E-commerce: The L5 Mini Forklift AGV can be utilized in retail environments such as supermarkets or large retail stores to restock shelves with products. In e-commerce warehouses, it can efficiently handle order fulfillment by picking items from shelves and preparing them for shipment.

Cold Storage Facilities: The L5 Mini AGV can operate in low-temperature environments, making it suitable for applications in cold storage facilities. It can move products in and out of refrigerated or frozen areas, helping maintain the integrity of temperature-sensitive goods.

L5 forklift small AGV material handling applications can vary across industries and include tasks such as:

Transporting raw materials from storage areas to production lines.

Moving work-in-progress items between different stages of production.

Palletizing or de-palletizing goods.

Loading and unloading trucks or containers.

Sorting and distributing products in warehouses.

Assisting with order fulfillment and picking operations.

Moving heavy or bulky items within a facility.

Recycling or waste handling.

L5 mini forklift robot material handling AGV offer enhanced efficiency, safety, and productivity in material handling operations, making them a valuable tool for industries seeking to optimize their supply chain and production processes.

The lifting capacity of the L5 forklift AGV for material handling can vary depending on the specific model and configuration. Generally, it is designed to handle loads ranging from a few hundred kilograms up to a ton or more.

Yes, the L5 mini forklift AGV is specifically designed to operate in narrow spaces and confined areas. Its compact size and maneuverability allow it to navigate through tight aisles and congested environments with ease.

The L5 mini AGV is typically powered by rechargeable batteries. Charging stations or battery swapping systems can be implemented to ensure continuous operation and minimize downtime.

(1).webp)

.webp)

.webp)