Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

The Intelligent Revolution: The Essential Path to Efficient Production, Cost Reduction, and Enhanced Efficiency

A leading automotive company's headlight factory – Headlight Factory · Component Delivery

In the current development trends of the automotive industry, headlight factories are facing numerous challenges and opportunities. With the continuous evolution of autonomous driving technology and the expansion of the electric vehicle market, headlights, as a crucial component of automotive exterior design, need to constantly enhance their technological sophistication and functionality. Therefore, headlight factories must continuously innovate and improve production efficiency to meet market demands.

In this context, the application of automation and intelligent technologies has become an inevitable choice for the development of headlight factories. Automated Guided Vehicles (AGV/AMR), as automated handling equipment, can perform tasks such as material transportation and production line logistics within factories, significantly boosting production efficiency and line flexibility.

In the automotive parts manufacturing sector, challenges such as highly customized demands, production efficiency pressures, material management difficulties, and rising labor costs are faced by companies. As a leading enterprise in the automotive industry, the headlight factory of this company urgently needs to introduce automated handling equipment to improve production efficiency, reduce costs, and enhance production line flexibility.

AGVs (Automated Guided Vehicles) / AMRs (Autonomous Mobile Robots), as an automated material handling solution, can meet the needs for material transport, production line connection, production flexibility, and labor replacement, laying the foundation for the company to achieve intelligent and automated production.

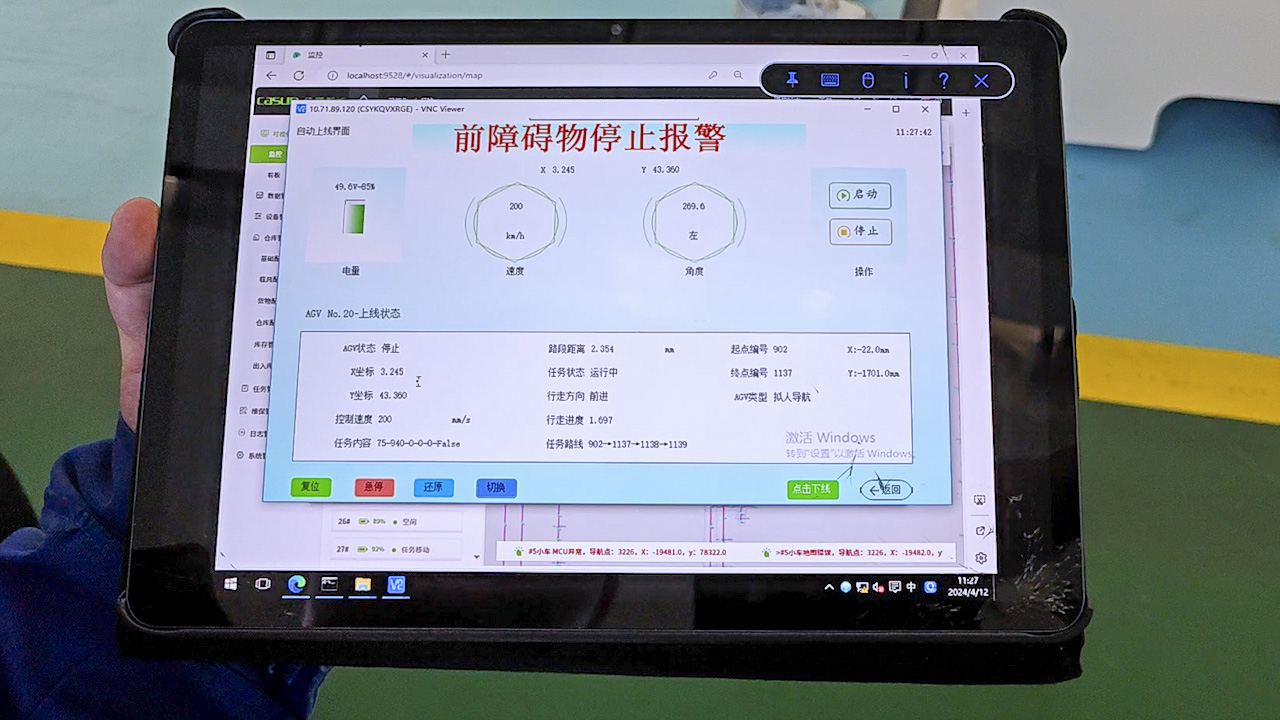

Complex production environment: The manufacturing process involves multiple production stages and a complex factory layout. The AGVs need to navigate and operate flexibly in tight and dynamic environments.

Diverse materials: The materials used in the headlight production process are varied. The AGV system must accommodate the handling of materials in various shapes and sizes, while ensuring stability and safety during transportation.

Cost control: While improving automation levels, companies need to consider the overall cost investment and return on the project to ensure the economic benefits of the AGV system.

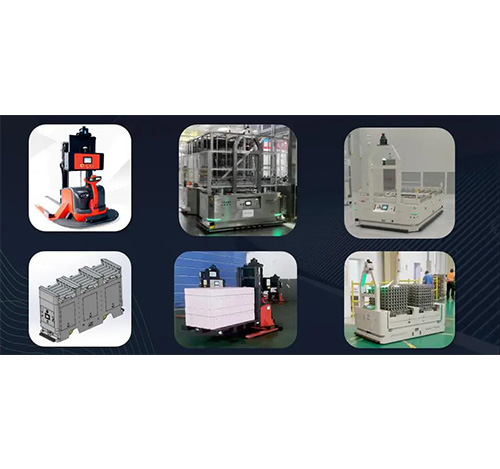

The project mainly utilizes latent lifting, rear towing, and forklift-type mobile robots, which are involved in several key stages of the production process.

In the warehouse area, autonomous forklifts are used to handle the inbound and outbound transportation of raw materials, optimizing warehouse space utilization and enabling precise inventory management. This ensures that material supply to the production line is timely and accurate.

For different production processes, small items are handled by latent lifting type mobile robots, while larger items are managed by rear towing mobile robots, completing tasks such as receiving and feeding materials to ensure smooth material flow.

The CRMS system collects and transmits real-time status data of material transportation. By integrating with the factory's production management system, it enables full-process monitoring and management of the production flow, optimizing production scheduling and logistics paths.

Improving production efficiency: The CRMS system enables the automatic and continuous handling of materials for multiple vehicle models. The use of AGVs/AMRs helps reduce bottlenecks in the production process, improving the speed and smoothness of transitions between different production stages.

Reducing labor costs: AGVs/AMRs replace a large amount of manual material handling, lowering labor costs while also reducing the potential damage and errors that may occur due to manual operation.

Optimizing inventory management: The CRMS system is integrated with the warehouse management system to enable real-time tracking and inventory management of materials. This improves inventory accuracy and efficiency. Through precise material delivery, unnecessary inventory occupation in the production process is reduced, optimizing warehouse space utilization.

Cost reduction and efficiency improvement: The overall efficiency of the production line has been enhanced, while labor costs have been reduced.

Optimizing inventory management: Real-time tracking and inventory management of materials have been achieved, improving the accuracy and efficiency of inventory management.

Integrating production line data flow: The production process is now efficiently, intelligently, and seamlessly connected.