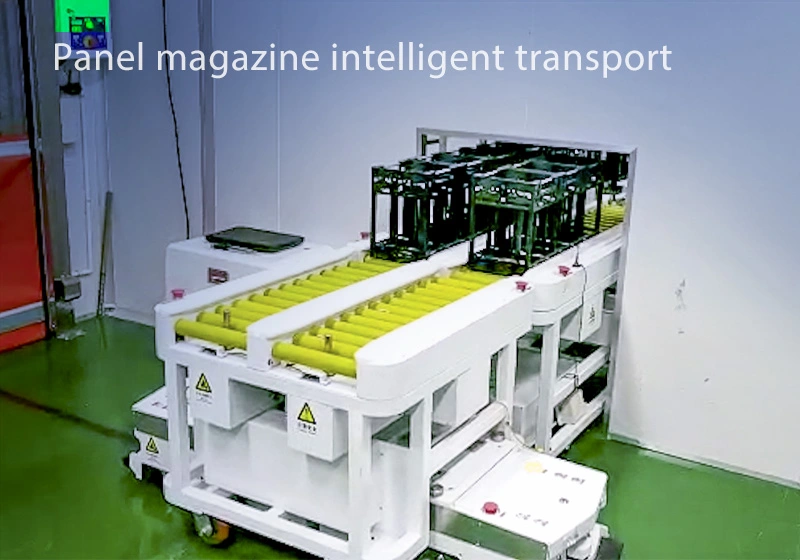

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

| Forklift type | Handling Type | Moving direction | Forward, backward, rotate |

| Dimension | L1585*W780*H2035 (mm) | Drive mode | Single steering wheel drive |

| Fork size | 1170*188*55 (mm) | Acceleration | 0.35 m/s² |

| Fork outside distance | 570mm/680mm | Max moving speed | 1.2 m/s |

| Max load capacity | 1000kg | Max climbing capability | ≤3° |

| Truck weight(battery included) | 400kg | Battery type | Lithium battery |

| Turning radius | 1350mm | Charging mode | Side charging |

| Lifting height | 120mm | Charging time | ≤1H |

| Pallet type | Two-way Entry | Rated endurance | 6H |

| Pallet size | 1200*1000mm / 1100*1100mm | Safety warning | ●Light warning ●Voice broadcast |

| Navigation mode | Laser positioning navigation | Safe sensing range | ≤3m adjustable |

| Navigation accuracy | ±10mm | Safety protection |

|

| Stop accuracy | ±10mm | Fork protection |

|

| stop angle accuracy | ±1° | Working temperature | -10℃~45℃ |

| Communication Method | WiFi / 5G | Working Environment | No dust, no flammable/explosive/corrosive gases |

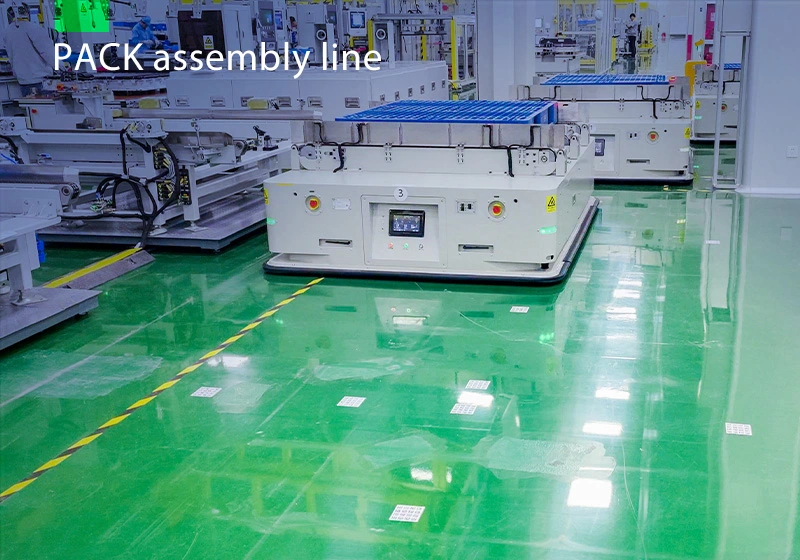

Workable in narrow aisles with width of only 854mm ~ 900mm, canl also do challenging jobs like 90-degree turning a corner or 180-degree in-situ rotation & turning around in narrow space.

Compared with ordinary forklift trucks, the storage capacity of goods can be increased by 20% when placing goods in parallel.

It can be linked with ordinary elevators,can realize 2 forklifts synchronized in & out of the elevator, so as to greatly improve operation efficiency.

Workable across floors with similar map scenario, greatly meet the requirements for material transfer across floors.

Unique dual wheel differential drive, fast speed (0-60 meters only needs 3 seconds), and with fast rotation function (in situ rotation only 4 seconds).

It can be quickly put into use without on-site transformation of the application.

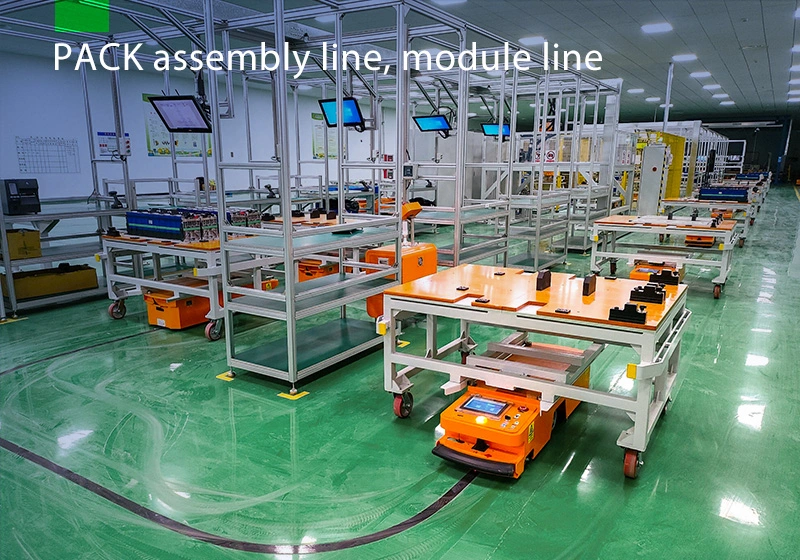

Independent operation according to scheduling instructions, without manual intervention in the production process.

Perfect fault self-check function, and have remote fault diagnosis and self-recovery function.

AGVs will move to charge station and do charging job automatically when they are detected to be in low power status,response time can be 24 hours per day so as to increase productivity.

Equipped laser obstacle detection sensor, mechanical anti-collision device and acoustic-optic warning to ensure safe operation.

(1).webp)

.webp)

.webp)