Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Automated Tugger series AGV can tow the material cart at the rear and can tow multiple carts at a time. At the same time, AGV tuggers can also place pallets, racks, bins and other goods on the car body for transportation. The navigation method can choose magnetic navigation and laser navigation. The towing capacity of the tugger AGV can reach 4500kg. This series of AGV machinery has a wide range of applications and a high degree of automation. The Automated Tugger AGV is widely used in many industries such as flat panel displays, new energy lithium batteries, automobiles and spare parts, food and beverages, 3C electronics, home appliances and so on.

Cargo can be transported fast and flexibly by using a automated tugger AGV/AMR. The AMR/AGV tugger improves operational efficiency through a predictable and consistent workflow and increases the safety of workers, products, and equipment through precise and controlled movement, thereby reducing the typical operating costs and concerns of a traditional forklift truck.The AMR/AGV tugger has an optional automatic suspension function, allowing the vehicle to automatically connect to or decouple from a trailer or trolley.

Our automatic tugger AGV/AMR is perfect for trolley carts, and AGV tugger carries more cargo per trip compared to other tugger AGVs.

Magnetic navigation / SLAM navigation

0-45m/min

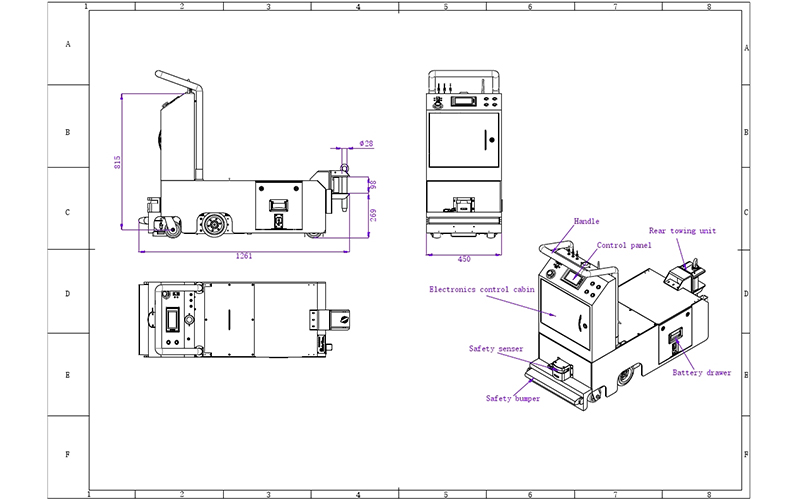

L1250*W450*H865 (mm)

800mm

±15mm

Forward, turn left&right, backward≤2m

600kg / 1200kg

Differential drive

Magnetic navigation / SLAM navigation

0-45m/min

L1307*W650*H913 (mm)

800mm

±15mm

Forward, turn left&right, backward≤2m

1500kg / 2000kg

Differential drive

Laser navigation / SLAM navigation

1.5m/s / 1.2m/s

L1853*W966*H2237 (mm)

1500mm

±10mm / ±15mm

Forward, turn left&right, backward≤2m

3000kg

Steering wheel drive

Laser navigation / SLAM navigation

1.5m/s / 1.2m/s

L2427*W1183*H2149 (mm)

2000mm

±10mm / ±15mm

Forward, turn left&right, backward≤2m

5000kg

Steering wheel drive

The tugger AGV/AMR mainly performs magnetic tape or laser navigation method, and they are both featured by a stable operation. If needed, tugger AGV/AMR could also be adapted to SLAM navigation.

This type of AMR/AGV tugger hauls cart with its rear tow bolt. The cart can be manually hitched or it can be designed to hitch and unhitch carts automatically.

Being able to haul multiple carts at the same time, the max. The payload of AMR/AGV tugger is up to 5000Kg.

The rear towing type automated tugger AGV/AMR is able to travel outdoors with a water-proof design, thus achieving efficient cross-plant transportation of material.

The Tugger AGV/AMR can match various types of carts with the caster. With the combination of carts and AMR/AGV, a flexible production line is formed, thus fast transportation of material in the factory is realized.

The tugger AGV/AMR can tow multiple carts at the same time to meet the on-site need for transportation.

The tugger AGV/AMR could be applied in various industries because it includes multiple AMR/AGV types, thus they have been widely applied in automotive,3C electronics, lithium battery, warehousing and logistics, semi-conductor, and home appliances industry.