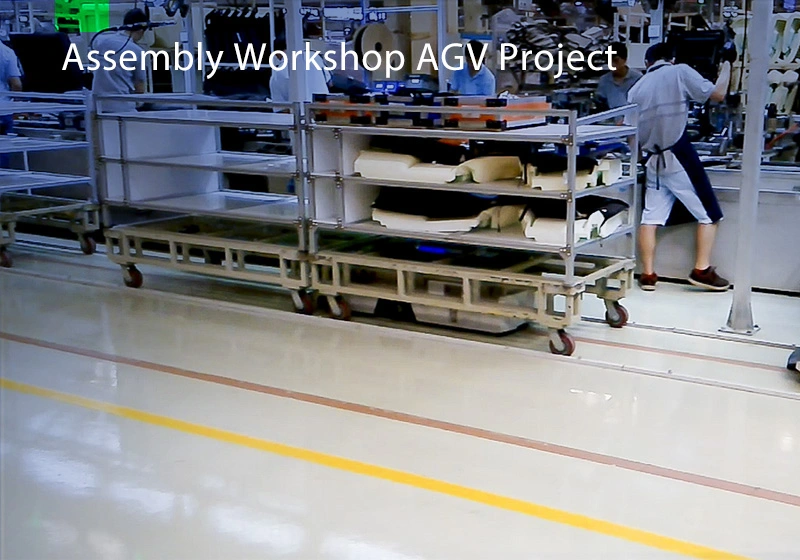

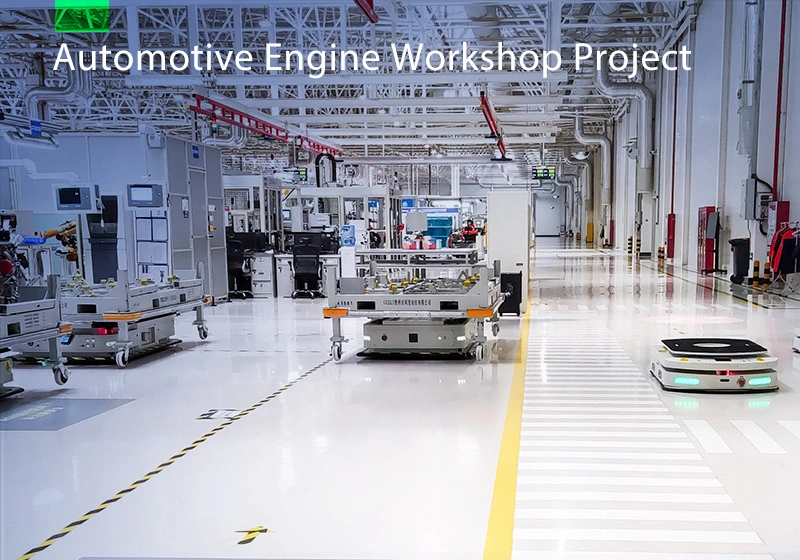

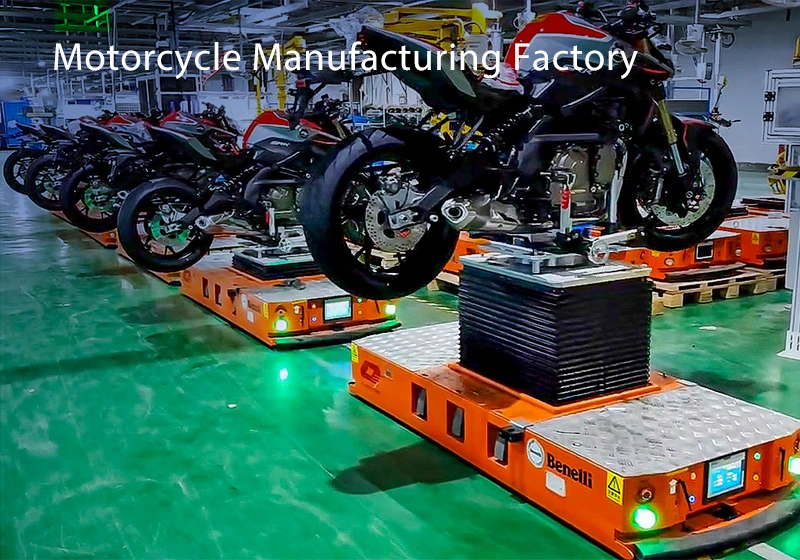

Focus on AGV industry for 18 years

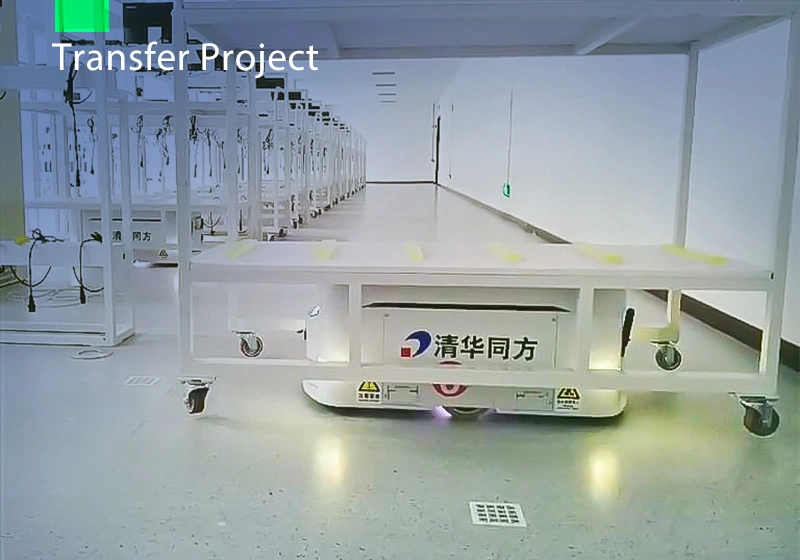

Focus on AGV industry for 18 years

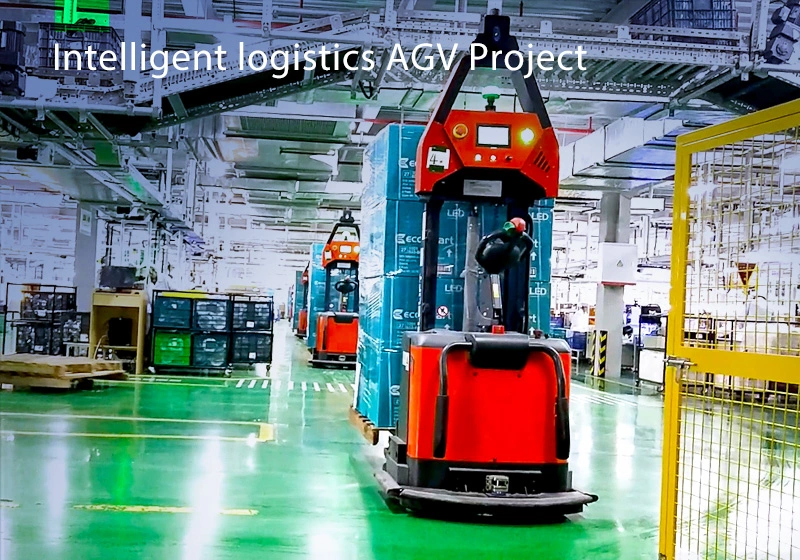

Focus on AGV industry for 18 years

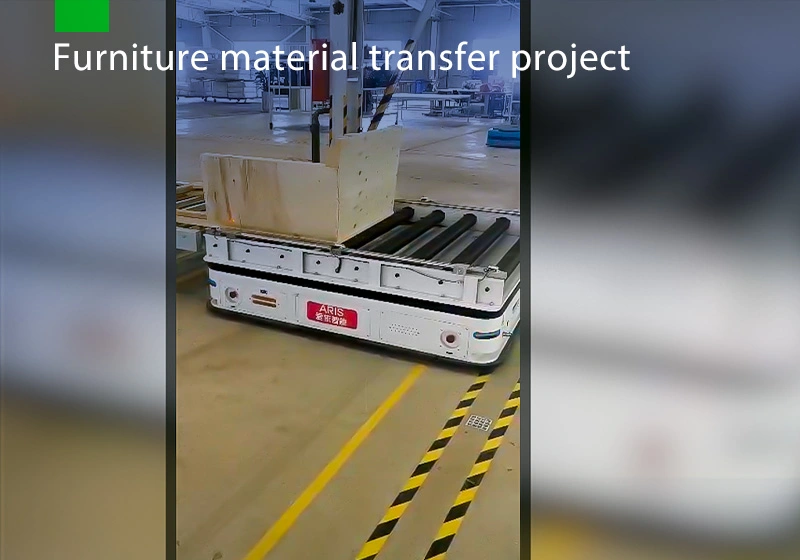

Focus on AGV industry for 18 years

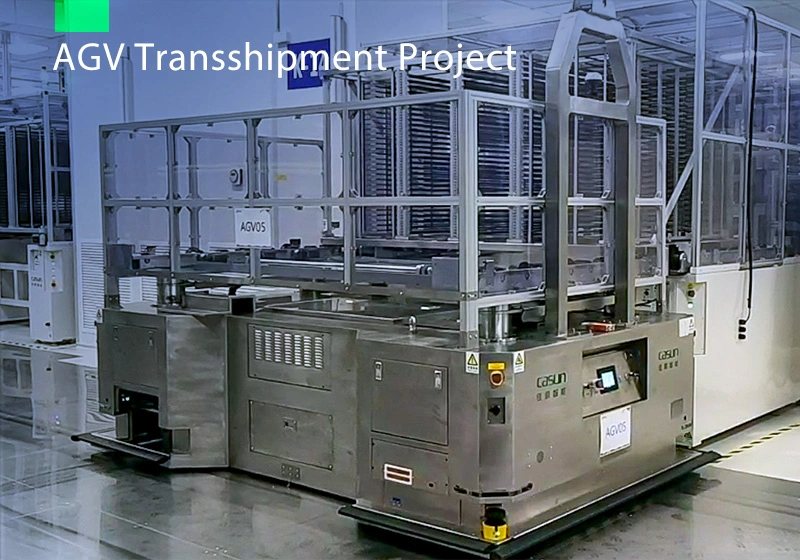

| Dimensions | L3500XW2150XH2785mm | Drive mode | Steering wheel drive |

| Max payload | 1000kg | Acceleration | 0.35m/s² |

Vehicle weight | / | Max moving speed | 1.0m/s |

| Rotation diameter | / | Max climbingcapability | ≤3° |

Docking height | 1300mm | Battery type | Lithium battery |

| Material supporting size | / | Charging mode | Side charging / Ground charging |

Docking direction | Forward, backward | Charging time | Charging time after full discharging≤1H |

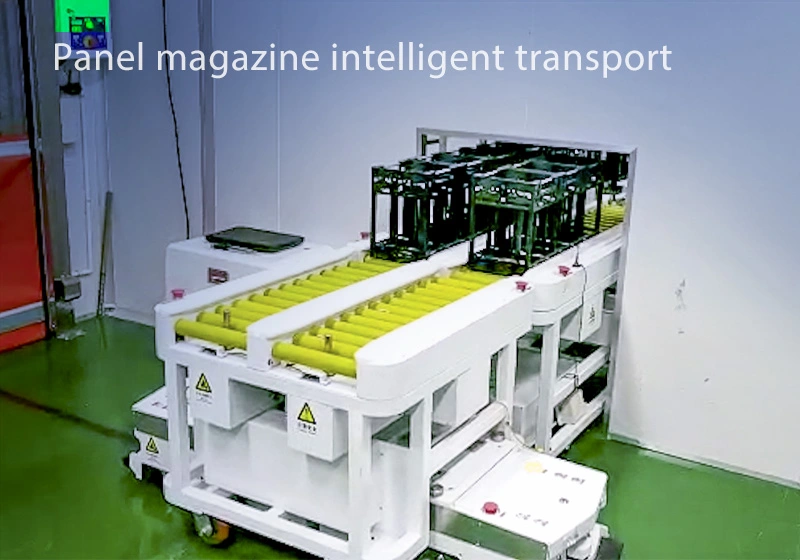

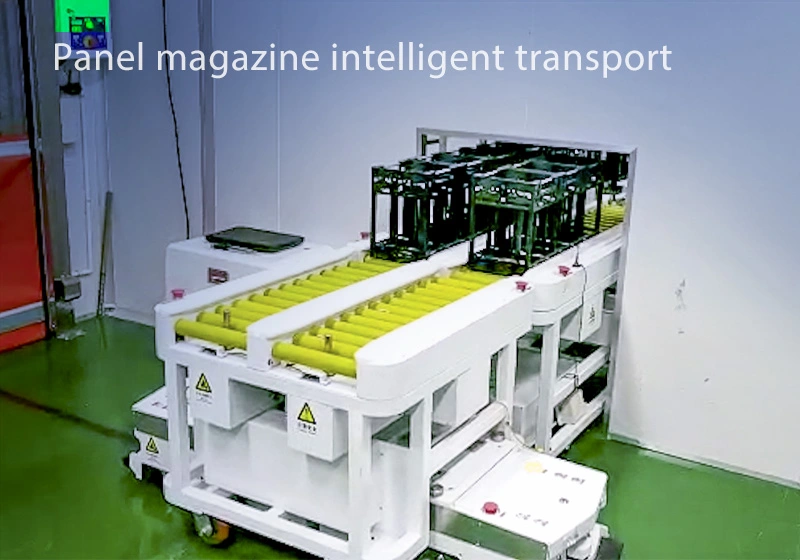

Material transfer mode | Roller | Rated endurance | 8H |

Navigation mode | QR code navigation/Laser navigation | Communication Method | WiFi / 5G |

Navigation accuracy | ±10mm | Safety warning | ●Light warning ●Voice broadcast |

Stop accuracy | ±10mm | Safe sensing range | ≤3m adjustable |

Stop angle accuracy | ±1° | Safety protection |

|

| Moving direction | Forward, backward, rotate, sideways | Application Environment | -10℃ ~ 45℃,No dust, no flammable/explosive/corrosive gases |

At the same time, it has the functions of 90-degree turn, 180-degree turn and side shift.

The device adopts vibration reduction design, which can ensure the operation of goods that need vibration.

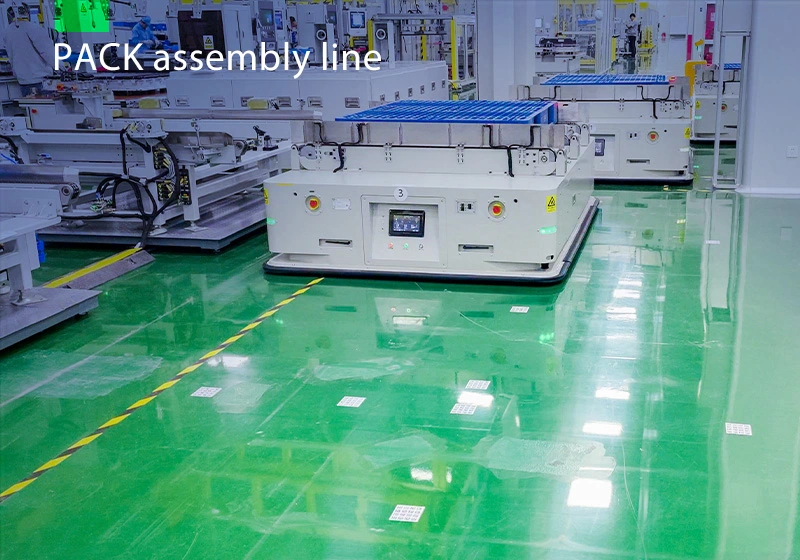

It can communicate and interact with ordinary elevators, and use elevators to complete up and down stairs.

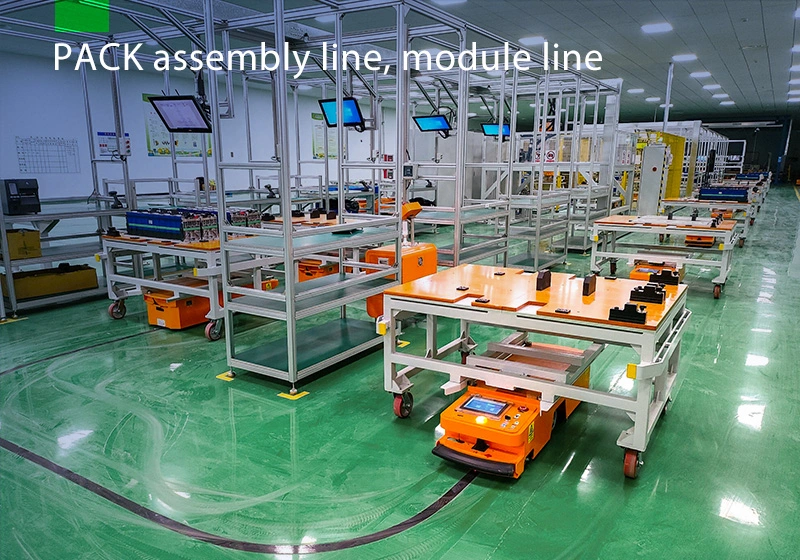

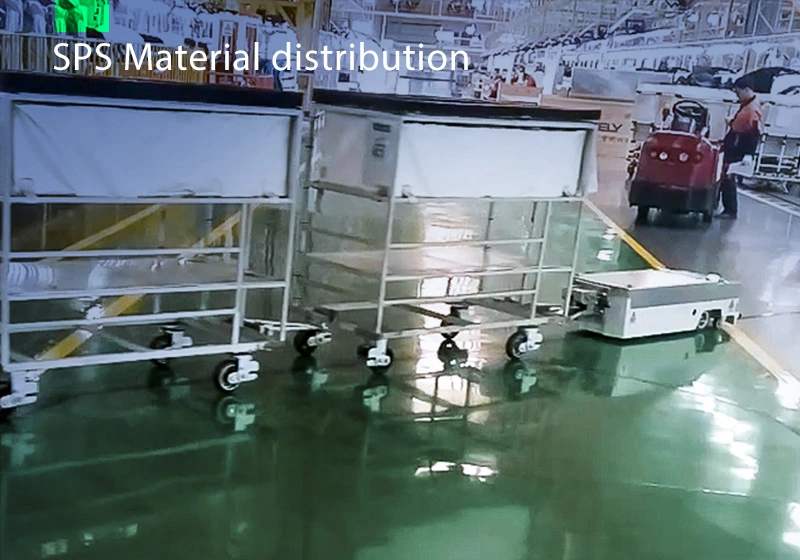

Synchronous scheduling of multiple AGVs is suitable for complex material handling scenarios.

Operate independently according to scheduling instructions, without manual intervention in the production process.

It has perfect fault self-checking function, and has remote fault diagnosis and self-recovery function.

When the battery is low, it can be automatically charged at the charging station. And can realize 24 hours of uninterrupted operation, without manual intervention

Equipped with laser obstacle detection sensor, mechanical anti-collision device and sound, light and voice alarm to ensure safe operation.

(1).webp)

.webp)

.webp)