Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

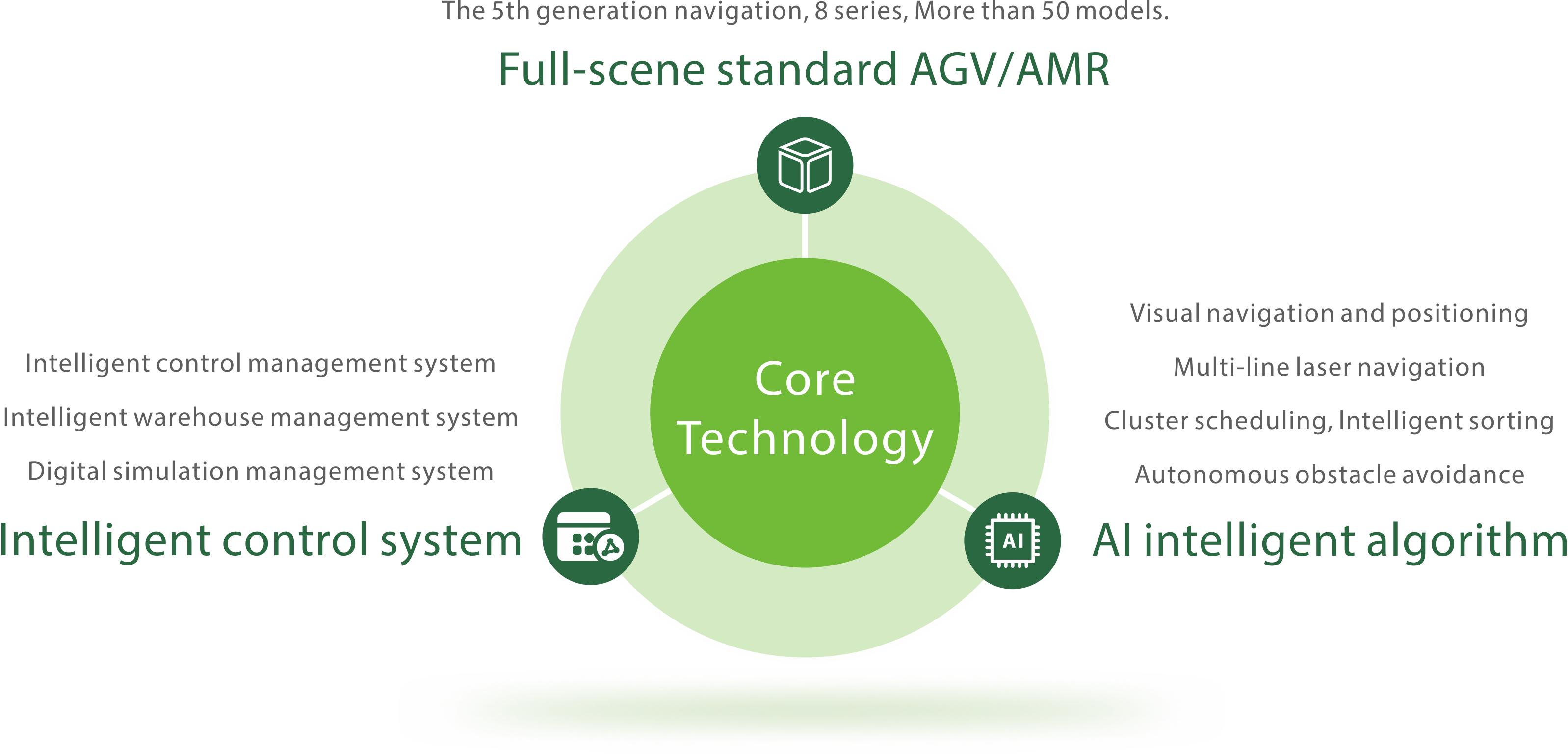

As a listed AGV company in NEEQ in China (stock code:834863), CASUN, one of the most professional AMR robot companies, has been focusing on AMR AGVs machinery and related AI robots since 2007. Casun's core products include AGV equipment, types of AGVs' intelligent control systems, intelligent algorithms, etc. According to the functional working modes, Casun's types of AGVs for sale can be divided into 8 series with more than 50 models and compatible with 5-generation navigation modes.

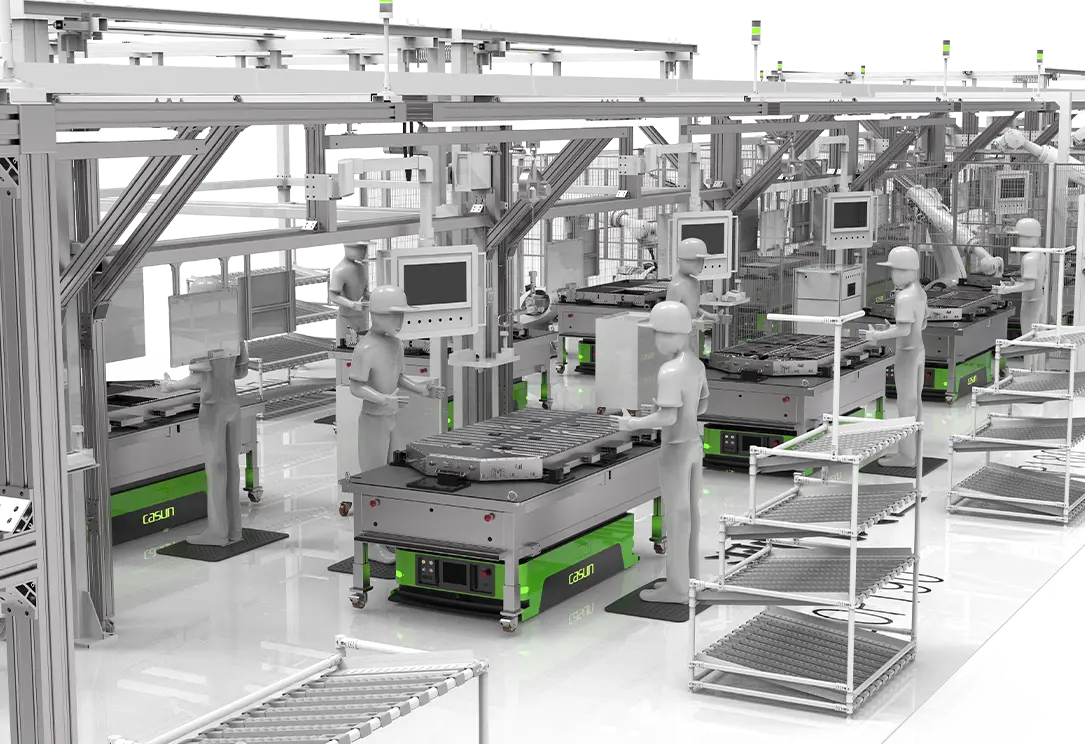

The AMR/AGV is a computer-controlled vehicle that uses computer software to determine the AMR/AGV car’s location and motion. These AI AMR/AGVs sales are powered by a battery or motor and are capable of manufacturing, storage, loading, and other operations without human interference. Self-powered AMR/AGV auto can perform load transfer, move, and stack pallets, complete assembly, and drag loads that have previously been done by people. Various kinds of AMR/AGV(Automated Guided Vehicle) types improve productivity, remove humans from both unsafe and potentially dangerous environments, and overcome possible human error.

As an experienced AMR/AGV mobile OEM manufacturer, CASUN provides many types of autonomous mobile robots at the best AMR/AGV(Automated Guided Vehicle) price, which includes Latent Lift AGV/AMR, Load Shifting AGV/AMR, Forklift AGV/AMR, Tugger AGV/AMR, etc.

Rich implementation experience: CASUN has focused on mobile robot industry for 17 years, owning comprehensive application scenarios, 50+ industry coverage and rich implementation experience.

Mature product technology: with 5 generations of navigation technology and a full range of products, CASUN’s products have passed through MTBF(mean time to failure)2000 hours certification.

Strong innovation and application ability: professional and innovative technical team, 100+ invention patents and software Copyrights, and the whole system of products are constantly upgraded and iterated.

Quality and cost stability: a total of 28,000 + units have been delivered, CASUN owns a mature and stable supply chain system, stable quality, reliable delivery, and advantageous cost control.

Stable core team: CASUN has a pragmatic and stable management team, full ownership of core personnel, more than 54% of 10+ years seniority employees, efficient coordination and tacit cooperation.

Focus in AGV industry, rich application cases, comprehensive coverage of customers in all industries, rich implementation experience.

With mature 5 generation navigation control system, more than 50 standard models. The product series is comprehensive, covering all kinds of application scenarios.

Many years of precipitation, dedicated and professional R&D and application technical personnel, have a great innovative and customized capabilities.

Mature and stable supply chain system, quality, delivery time and cost advantage guaranteed;

Pragmatic and steady management team, with a clear strategic planning and market positioning.

The working order of the AMR/AGV mobile car is as follows: the central controller, after receiving the cargo handling instruction, conducts vector calculation and route analysis according to the predrawn operation drawing and selects the best driving route. It automatically and intelligently controls the driving of the AMR/AGV auto, turns on the road, and ensures the AMR/AGV reach the accurate parking position of the loaded goods and load the goods. The autonomous industrial robots then begin working and running to the target unloading point, stopping and completing the unloading after reaching the exact location and reporting their location and status to the control computer.

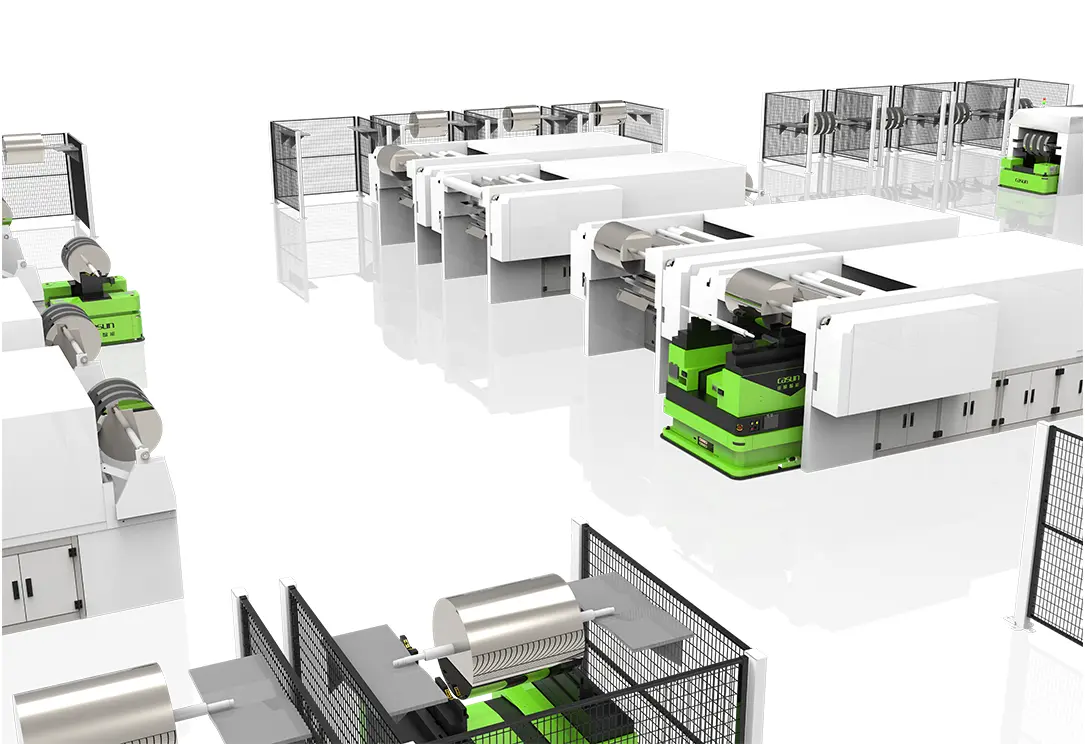

The project is for raw materials transfer in the assembly workshop of an automobile factory. Multiple SLAM lifting AGVs are used to build a flexible production line, and intelligently distribute materials on-demand to meet individual and flexible customized production needs.

Latent lifting AGVs are used in this kind of project for polarizers materials handling, laser-guided roller AGV are used for transporting packing materials; AGV control systems working together with MES systems are used to realize functions of intelligent scheduling and production line interaction.

QR code roller AGVS are used for material transfer from the warehouse to finished product production line. Working with MES system, it can automatically send out calling orders, and realize fully automated and informatized material distribution.

Stacking forklift AGVs can realize automatic distribution function. The AGVs can be equipped with an automatic weighing device to check weight first and then decide to deliver materials to the task points. Besides,the AGVs can also be equipped with visual inspection systems that can correct deviations by itself and improve the docking accuracy for the forklifts and bins.

QR code latent lifting AGVs are used in logistics transfer center for finished products in & out process and to realize unmanned intelligent sorting: AGVs working together with manipulator realizes warehouse intelligent sorting process for finished products in & out. 190 round trips per hour, average 18 seconds each time.