Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

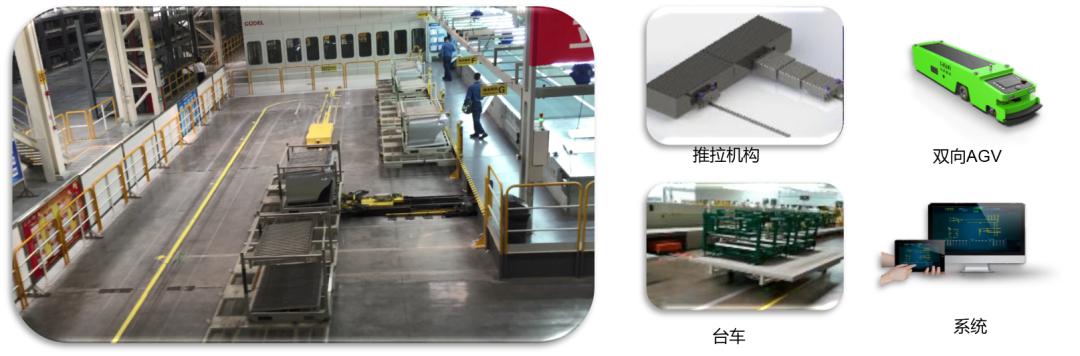

1. Stamping workshop

In the stamping workshop, the conventional application method is to use a two-way magnetic track latent traction AGV to independently realize the exchange of empty idle cars, and then complete the transfer and data collection of stamping parts. The advantage of this solution is that it is mature and stable, and has a significant price/performance ratio.

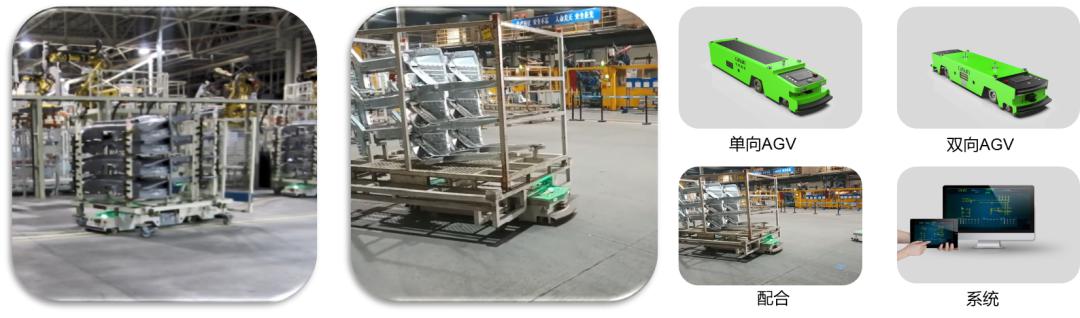

2. Welding workshop

In the stamping workshop, the conventional application method is to use a two-way magnetic track latent traction AGV to independently realize the exchange of empty idle cars, and then complete the transfer and data collection of stamping parts. The advantage of this solution is that it is mature and stable, and has a significant price/performance ratio.

3. Welding workshop

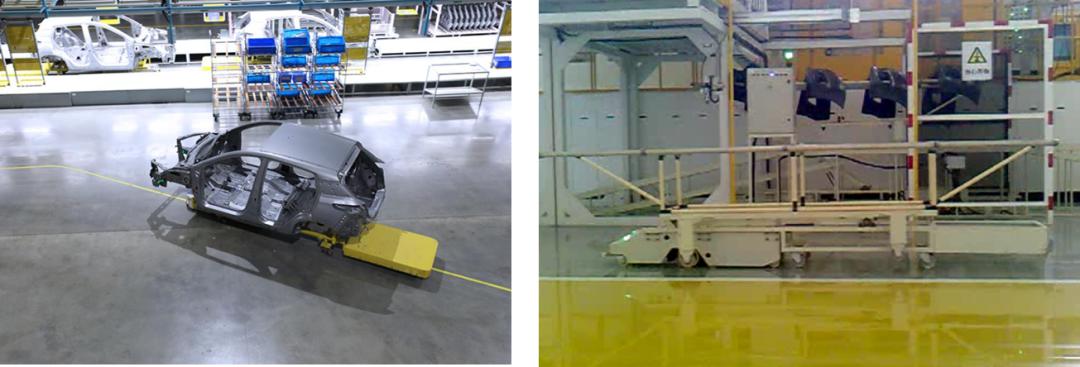

Although there are relatively few AGV vehicles used in the painting workshop, the conventional solution is still the way of latent traction of magnetic navigation AGV to form a circular production line, and material transfer and data collection have never been completed.

4. Assembly workshop

The final assembly workshop is the scene where the AGV queue is the most widely used and the largest in scale as a flexible production line, achieving efficient production takt time. While saving manpower, it reduces the investment in fixed assets and meets the flexible production needs of small batches and multiple batches.

After the practical application of more than 100 projects and more than ten years of development, CASUN Intelligent has now explored some innovative applications in the automotive industry. These include technological innovation and application scenario innovation.

1. Application technology innovation

In terms of motion navigation methods, AGV products have become more and more mature after years of development. At present, they have made great progress in speed, accuracy, navigation methods and communication methods, such as visual navigation, multi-line laser and hybrid navigation technology. The successive applications have made AGVs more flexible as the carrier of smart logistics in the field. With the help of 5G communication, the large-scale application of flexible production lines has been promoted.

In terms of perception technology, AGV vehicles have transitioned from single intelligence to group intelligence, multi-machine collaboration, autonomous obstacle avoidance, visual recognition, autonomous deviation correction, queue following and human-machine interaction, which further strengthens the process of unmanned factories.

From the perspective of system capabilities, cross-floor, multi-scenario, hybrid navigation, and large-scale scheduling can collect data and track the full life cycle of products while realizing material transfer, thus forming a closed data loop and facilitating management and decision-making.

Taking the CASUN intelligent control system as an example, based on the big data platform, it can be connected with various production management systems, material management systems, and warehouse management systems upward, and downward, it can be connected with various production equipment, such as manipulators, conveyor lines, and air showers. Doors, elevators, etc. At the same time, remote control can be realized through different terminals such as mobile phones, tablets, and computers. The accompanying digital simulation function can simulate the monitoring of production process planning and operation status.

2. Application Scenario Innovation

On the basis of the above-mentioned innovative technologies, more innovative application scenarios are also derived and extended in various technological processes of OEMs. Next, I will focus on four more common and representative application scenario innovations.

The first is the door assembly line of an automobile assembly shop in South Africa. The AGV is used to carry the QR code instead of the traditional suspension line to complete the assembly action and realize flexible production, which not only improves the space utilization rate, but also reduces the investment cost of fixed equipment.

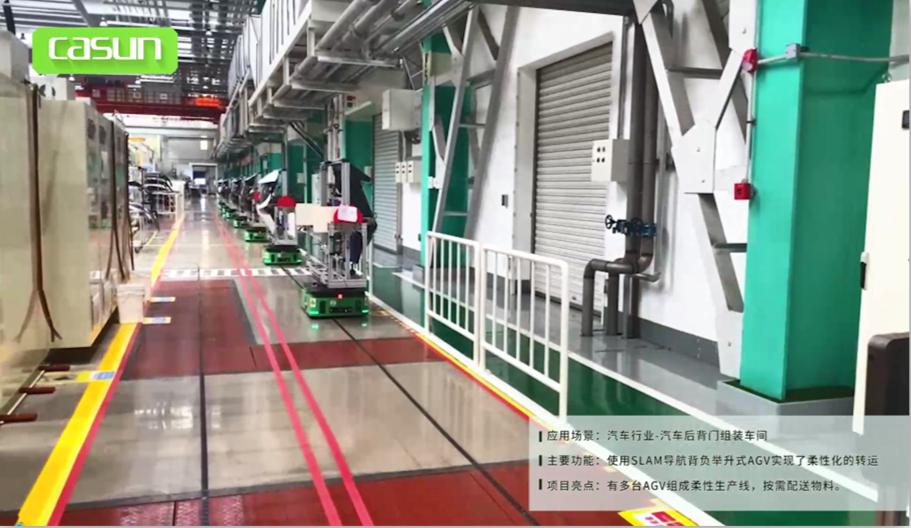

The second is the rear door assembly workshop of a car factory in Tianjin. The SLAM navigation and lifting AGV is used to form a flexible production line according to the production line operation rhythm and on-demand ingredients. While satisfying personalization and customization, it can improve production efficiency.

The third is the scene where the outdoor AGV is docked with the flying wing vehicle in the logistics planning of a well-known car yard. Through the automatic navigation of the forklift AGV, visual positioning and visual recognition technology are used to connect with the flying wing vehicle to realize the function of automatic loading and unloading. The collection node that advances the data stream forward.

The fourth is to use the forklift AGV to connect with the shelf to realize loading and unloading, connect with the material frame to realize intelligent handling in the warehouse, and connect with the vertical warehouse to realize the warehousing link.

The above four scenarios represent innovative applications in solutions and scenario extension respectively. Of course, there are more logistics scenarios and demands of various forms in the automotive and auto parts industry chain. We will continue to explore and precipitate to do a good job in the automotive industry. Comprehensive planning of smart logistics.