Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

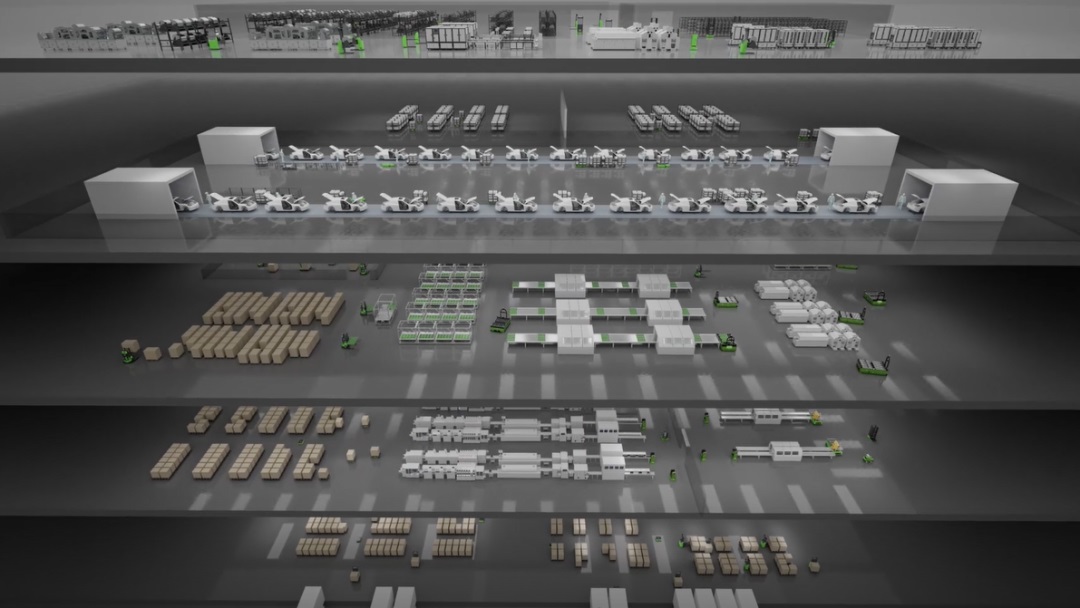

2023 CASUN Innovative Product Development and Product Operation System Project officially launched, focusing on the collision and polishing of technology and demand to upgrade a series of products in the era of explosive growth, displaying brilliantly.

C2-37 SLAM-guided latent lift mobile robot

The era of big data has catalyzed more flexible and intelligent upgraded logistics products, highly accurate identification of scenes and their fused information, and accurate sensing and modeling of the surrounding environment through the acquisition of multi-source information.

It can perform high-precision, time-consuming and harsh environment work; intelligent decision-making, flexible execution and precise control; effectively enhance production efficiency and efficiently complete target tasks; unify product quality and guarantee personal safety; and autonomously respond to unexpected situations in the execution process.

Combined with intelligent decision-making and control at the software level, it further accelerates adaptation to the environment, thus ensuring efficient operation of robot clusters.

Flexible and efficient

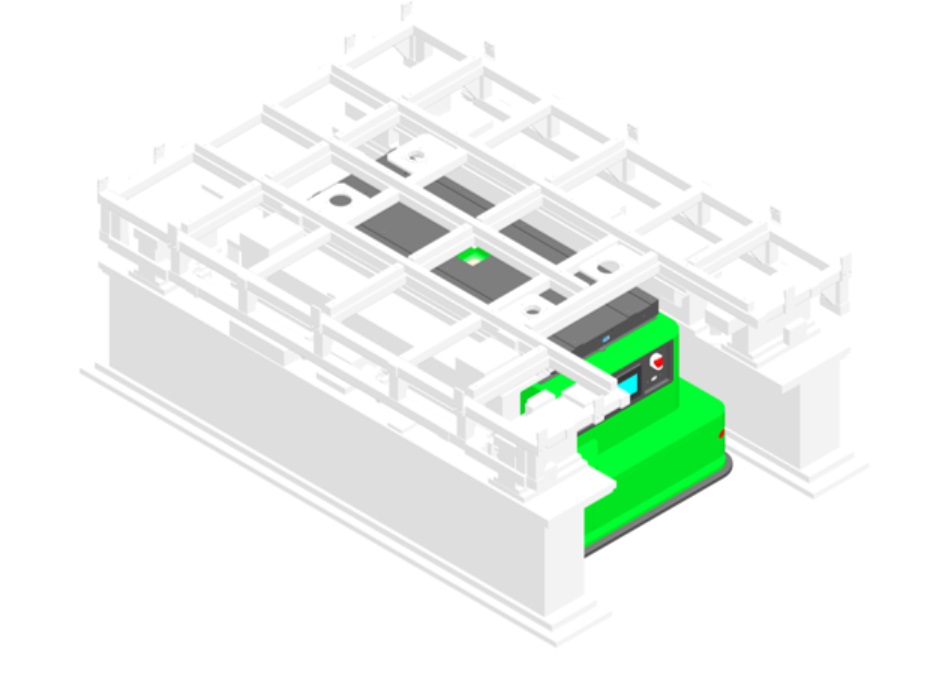

As a new online family members, the value and strength of one can not be missing. The forward-looking exterior design is strong and durable, and the polyurethane shock-absorbing casters ensure that no trace is left on the ground during walking. I dare and adept at meeting the challenge of "on-demand", can be used in new and old "smart" scenarios. Flexible adaptation. Strength in both appearance and performance.

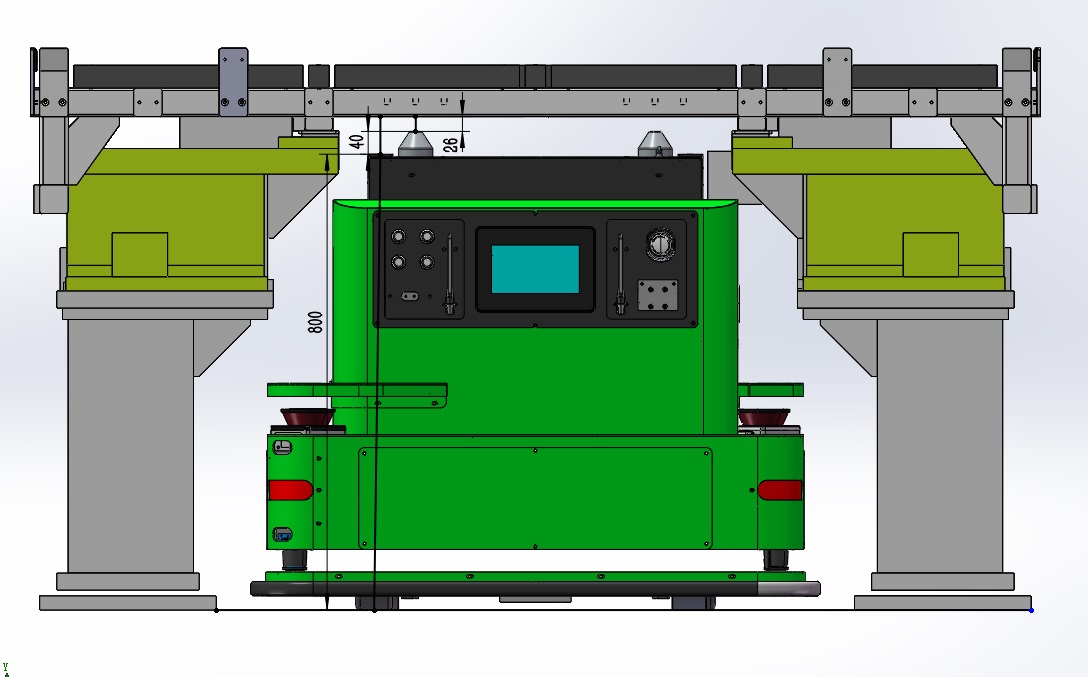

Beyond the ordinary maximum jacking stroke of 60mm, up to 248mm, applicable to a variety of height of the workstation and adapt to a variety of specifications of the battery pack.

Equipped with sweeping dock and material sensing travel switch, positioning pin; all fall into place before transmitting the signal, allowing me to achieve accurate car body positioning and material docking.

90 ° turn, 180 ° in situ turn around, 360 ° in situ rotation; lateral movement and other operating methods can also be easily coped with.

Intelligent navigation

Equipped with dual laser SLAM navigation sensors to measure and scan the surrounding environment and other landmark objects and identify them, thus building the surrounding environment into the navigation map system, effectively reducing auxiliary accessories and improving operational stability.

My eyes are the ruler, to ensure that I can walk the precise stop in place, to avoid damage to materials due to human operation irregularities or negligence.

Relying on the high-speed transmission of 5G, I can enhance real-time response and obstacle avoidance capability according to various dynamic changes, and realize tasks such as automated warehouse management and logistics distribution. Even if the workshop is upgraded and the site is changed, I can adjust and change the path according to the demand.

Flexible manufacturing

I am widely used in new energy lithium, automotive and parts, machinery manufacturing and other industries. I can be adapted to a wide range of battery packs and complete end-to-end transportation of production line materials and components. I can change the destination and path flexibly with the production plan to form a flexible production line.

I can save the investment of manpower and equipment for customers. Replacing traditional large conveyor lines, route and process changes can be accomplished by changing the program. Rapid cutover makes scheduling more flexible, thus meeting diversified production patterns.

High fault tolerance; mixed line transport function; automatic or manual handling to resume work quickly in case of failure. This greatly reduces customer cost investment and improves production turnover efficiency by more than 20%.

Accuracy of warehousing and timely supply of materials reaches 99.99%; damage to undesirable materials in the handling process is reduced by more than 90%, thus reducing the storage management area by more than 20%.

Multiple protection

With multiple protection functions; replace guardrail and safety carpet; greatly save customers' maintenance cost and reduce unnecessary downtime.

Automatic deceleration when encountering obstacles; automatic stop when reaching the stopping distance;; automatic start after the elimination of obstacles; induction detection range 0.1~25m adjustable; irradiation angle 0~360° range adjustable.

I dare and good at dealing with all kinds of risk, pressure. When in direct contact with obstacles, I will stop and sound and light alarm, and remind the device to do fault display and automatic power cut off. Human colleagues intervention before starting again, so as to protect the material and personnel safety.