Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

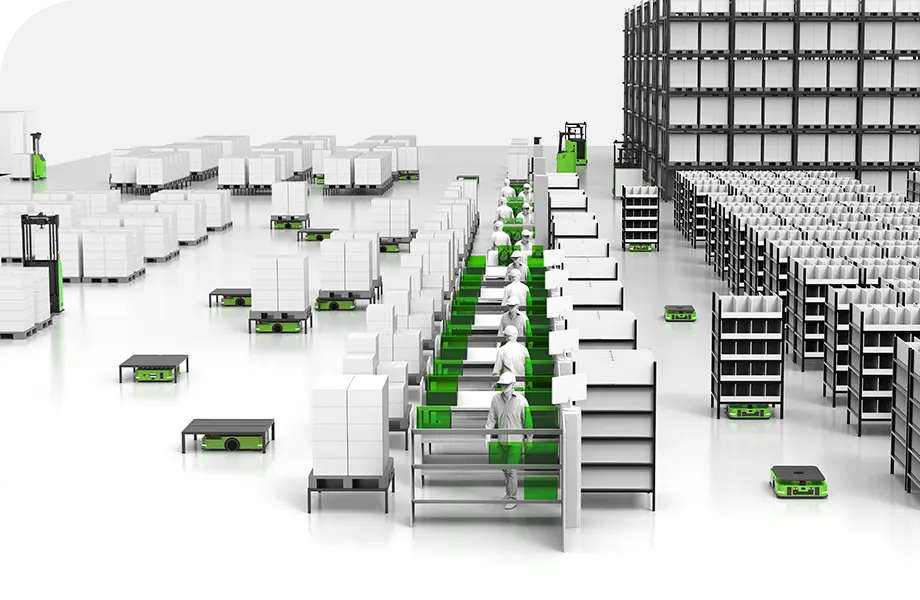

The emergence of AGVs has just solved the troubles of rising labor costs and strict requirements on efficiency. AGVs have promoted the pace of smart logistics. With the rapid development of modern smart cities, it has also accelerated the wide application of smart AGVs in multiple scenarios in manufacturing industry. AGVs from various AMR(autonomous mobile robots) manufacturers play an important role as an indispensable part of smart logistics.

1. As substitution for labors, intelligent robots can reduce labor costs and improve production efficiency.

2. In the production process, efficiency of logistics directly affects the efficiency of production. As an automated handling equipment, AGVs provide automatic on-line, automatic off-line, and midway transfer from products to materials, which are intelligent and unmanned transportation, which is a good solution to solve low efficiency problems in handling and sorting materials.

3. AGVs are vehicles under fully intelligent management, which improves management level and effectively avoids a series of factors of personnel management.

4. Product data management, material information tracking.

5. Narrow lanes, high shelves and compact layout storage, save land costs.

AGV China can realize back and forth transportation of loading/unloading materials, also realize non-stop refueling, shorten the time of manual refueling, and realize automatic charging, which can realize long-term work and greatly improve work efficiency.

AGVs are vehicles under fully intelligent management, which improves the management level and effectively avoids a series of factors of personnel management.

In comparison, AGVs are more efficient, driving path and speed are controllable, positioning and parking are accurate, and central management system can monitor AGVs all the way, reliability is greatly improved.