Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

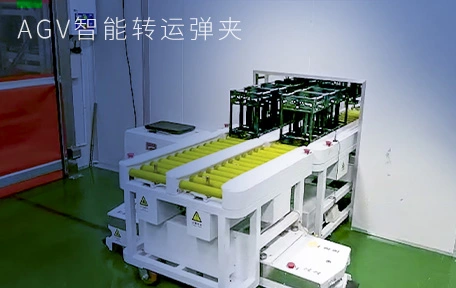

1. CBAK battery transshipment project is mainly applied in the field of new energy lithium batteries. Utilize smart transport magazine-clip of AGV,jointed with the multi-storey docking system, transport at the lower storey, and receive at higher storeys.

2. Difficulties of the project: High requirements for synchronization of the lifting accuracy of the docking terminal and the connecting accuracy with AGVs.

3. Functions and benefits provided by CASUN AGVs: By importing CASUN AGVs and customized stereoscopic warehouse transportation, which helps realize efficient transportation efficiency and material digital management level, and greatly increase efficiency of material transfer.

Manual operation is affected by various factors and is prone to errors. AGVs automatically transport materials according to the signal from the line to ensure the accuracy of delivery;

In order to meet fast-paced production, the demand for porters is large and working hours are long, which in turn leads to high salary costs and management costs;

The space utilization rate is low, and inventory cost is high.

1. The project includes 5 magnetic guided roller AGVs, 3 automatic charging stations, 2 lifting docking systems.

2. AGV dispatching system communicates with stereoscopic warehouse system and buffering storage location system.

3. Material picking and placing by stacking manipulator in stereoscopic warehouse to realize intelligent storage.

Connect with customers' MES and WMS systems to realize intelligent and digital management of automated production lines and material transportation, which greatly improves efficiency and digital level;

AGVs equipped dual-roller 4-station design, which transports 4 sets of material once, increase efficiency of material transportation;

All processes are seamlessly connected through AGV to improve the intelligence of the factory.